When you're milling lumber, the right chainsaw makes all the difference. Consider the Zozen Portable Chainsaw Mill for versatility and portability. The Granberg Chainsaw Alaskan Small Log Mill (G777) is perfect for compact jobs, while the Granberg Portable Edging Sawmill (G555B) offers stability for those longer cuts. If you need something larger, check out the 48 Inch Portable Planking Milling Bar. Finally, the Haddon Lumbermaker is quick to attach and versatile for various lumber sizes. Each option shines in different areas, and you'll want to know which one fits your needs best. Keep exploring for expert insights!

Zozen Portable Chainsaw Mill for Planking Milling

If you're a DIY enthusiast or a small-scale lumberjack looking for a versatile solution, the Zozen Portable Chainsaw Mill is an excellent choice for milling lumber. This mill assembles into three sizes, allowing me to work with planking bars ranging from 14 to 36 inches. Made from quality aluminum alloy and steel, it feels sturdy and durable. I love its adjustable milling height, which lets me cut slabs from 1/2 to 12 inches thick. Plus, the lightweight design makes it easy to transport to remote locations. I found the assembly straightforward, and the upgraded handle offers better control. Overall, it effectively transforms rough logs into high-quality lumber, making it a fantastic tool for various projects.

Best For: DIY enthusiasts and small-scale lumberjacks seeking a portable and versatile milling solution for various wood types.

Pros:

- Lightweight and portable design makes it easy to transport to remote locations.

- Adjustable milling height and width allows for cutting slabs from 1/2 to 12 inches thick.

- Positive customer feedback on ease of assembly and effective performance.

Cons:

- Some users report minor quirks in design that may affect usability.

- Vibration issues can occur, necessitating the use of locktite on securing bolts.

- Limited to manual operation, which may not suit everyone's needs for larger projects.

Granberg Chainsaw Alaskan Small Log Mill (G777)

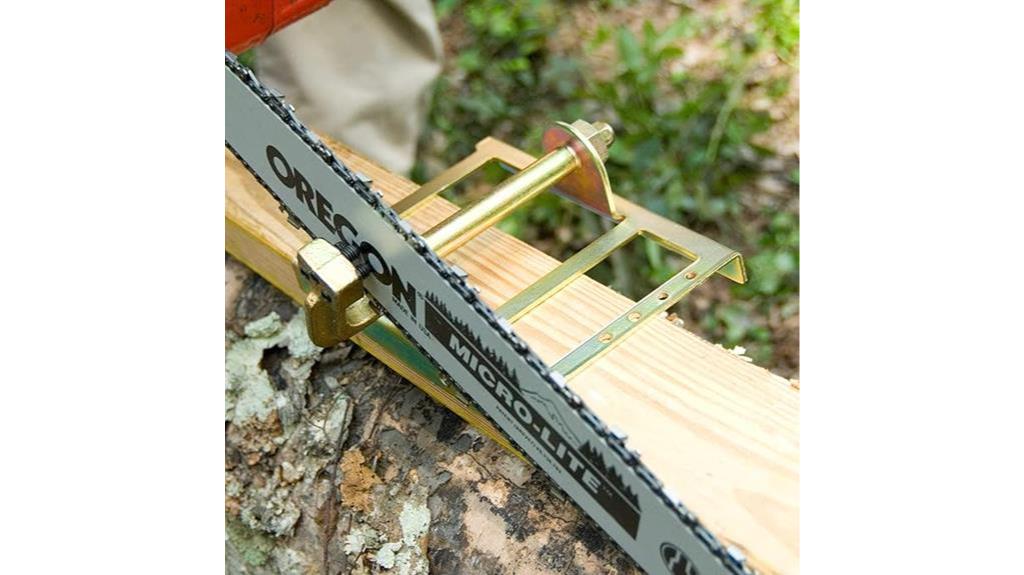

The Granberg Chainsaw Alaskan Small Log Mill (G777) stands out as an ideal choice for hobbyists and professionals alike who want to transform fallen trees into usable lumber. This portable sawmill attachment fits chainsaw bars from 16 to 20 inches and cuts lumber up to 18 inches wide and 13 inches deep. I appreciate its lightweight, compact design that clamps directly to the chainsaw bar without drilling. It's easy to assemble, and I recommend using a guide rail for straight cuts. To enhance your milling experience, use a ripping chain and keep your chains sharp, sharpening every two boards. With durable materials and great user feedback, it's a solid investment for anyone looking to mill their own lumber.

Best For: The Granberg Chainsaw Alaskan Small Log Mill (G777) is best for hobbyists and professionals looking to efficiently convert logs into usable lumber.

Pros:

- Durable construction with USA-made aerospace aluminum and zinc-plated steel ensures longevity.

- Ease of use with a lightweight, compact design that clamps directly to the chainsaw bar.

- Versatile compatibility with various chainsaw sizes and the ability to mill different wood types effectively.

Cons:

- Requires practice to achieve optimal cutting accuracy, especially for beginners.

- Dependence on a ripping chain for enhanced performance may necessitate additional purchases.

- Initial cuts may need guidance, which can be challenging without prior experience.

Granberg Portable Chainsaw Edging Sawmill (G555B) – 24 Inch Alaskan Mini Mill

For DIY enthusiasts and woodworkers looking to elevate their lumber milling game, the Granberg Portable Chainsaw Edging Sawmill (G555B) – 24 Inch Alaskan Mini Mill stands out as an exceptional choice. This mill is perfect for cutting timber logs, featuring 12 feet of V rail for stability. It requires a solid steel chainsaw bar and a minimum 50cc engine, ensuring durability. Made from aerospace aluminum and zinc-plated steel, it also includes a polycarbonate safety guard. Users can achieve precise vertical cuts to create dimensional lumber, thanks to the included wood screws and forming nails. While some may need extra V rail for longer logs, the overall feedback highlights its reliability and effectiveness in improving cutting precision.

Best For: DIY enthusiasts and woodworkers looking to enhance their lumber milling capabilities with a reliable and precise tool.

Pros:

- Durable construction using aerospace aluminum and zinc-plated steel ensures long-lasting performance.

- Includes support materials like wood screws and forming nails for enhanced cutting precision.

- User-friendly design allows for effective milling of various log sizes, making it suitable for both beginners and experienced users.

Cons:

- Additional V rail may be needed for longer logs, which could increase setup time and cost.

- Some users report a need for a more secure guard attachment for safety during operation.

- Requires a powerful chainsaw (minimum 50cc engine) which may not be accessible for all users.

Chainsaw Mill 48 Inch Portable Planking Milling Bar Size 14 to 48 Inch

Designed for both hobbyists and professionals, the Chainsaw Mill 48 Inch Portable Planking Milling Bar makes milling lumber an accessible task. It fits chainsaw bar lengths from 24 to 48 inches, allowing me to cut planks anywhere from 0.20 to 12 inches thick. The high-quality steel and aluminum construction makes it lightweight and totally portable, weighing only 8.6 kg. I appreciate how quick and easy it is to set up, clamping directly onto the chainsaw bar without drilling. The log milling attachment guarantees I get even cuts, and I can adjust the height and width for my lumber needs. Just remember to use a new ripping chain for best results. Safety glasses are a must, so gear up!

Best For: Hobbyists and professionals looking for a portable and efficient solution for milling lumber.

Pros:

- Lightweight and portable design at only 8.6 kg, making it easy to transport.

- Quick and easy setup with no drilling required, allowing for immediate use.

- Adjustable height and width for versatile milling options, suitable for various lumber thicknesses.

Cons:

- Some users report assembly issues, including missing parts and average craftsmanship.

- Recommendations for using blue Loctite on thumbscrews to prevent loosening may indicate design flaws.

- Safety concerns noted, requiring safety glasses and modifications for enhanced functionality.

Haddon Lumbermaker

Transforming your chainsaw into a versatile portable sawmill can be a game-changer for any DIY enthusiast or woodworker. The Haddon Lumbermaker makes this transformation effortless, attaching to your chainsaw bar in seconds and fitting all models. With it, I can cut lumber on-site, producing boards and beams of various sizes, from 2x4s to 2x12s. Made in the USA and backed by a lifetime guarantee, this tool guarantees accuracy by guiding along a secured board. I've found that it works best with hardwoods and larger logs. Just remember to keep your blade sharp and follow the installation tips for peak results. Overall, the Haddon Lumbermaker is an essential tool for milling quality lumber from downed trees.

Best For: The Haddon Lumbermaker is best for DIY enthusiasts and woodworkers looking to mill their own lumber on-site.

Pros:

- Easy to use: Attaches quickly to any chainsaw model, making it accessible for all users.

- Versatile cutting options: Capable of producing various lumber sizes, including 2×4 to 2×12.

- Durable construction: Made in the USA with a lifetime guarantee, ensuring long-lasting reliability.

Cons:

- Requires chainsaw experience: May not be suitable for inexperienced chainsaw users due to safety concerns.

- Performance limitations: Best suited for hardwoods and larger logs, which may limit its use in certain situations.

- Potential need for extra tools: Users might require additional Allen keys for adjustments, especially in remote locations.

Factors to Consider When Choosing Chainsaws for Milling Lumber

When choosing a chainsaw for milling lumber, you need to take into account several key factors. Power requirements, bar length compatibility, and the weight of the saw all play essential roles in your milling efficiency. Additionally, material durability and ease of assembly can greatly affect your overall experience and results.

Power Requirements

Power is a critical factor to contemplate when choosing a chainsaw for milling lumber. For effective milling, you'll typically need a chainsaw with a minimum engine displacement of 50cc. This capacity guarantees that your saw can handle the demands of cutting through larger logs and hardwoods without struggling.

You should also consider the power output, which is usually measured in horsepower (hp). A chainsaw offering at least 2-3 hp is ideal for most milling applications, as it provides the necessary strength for peak performance. Additionally, pay attention to the RPM (revolutions per minute); higher RPMs lead to faster cutting speeds, improving efficiency during the milling process.

Using a ripping chain specifically designed for milling can also enhance cutting performance, helping your chainsaw maintain its power throughout the job. Finally, remember to match the chainsaw's bar length to your milling attachment. Longer bars require more power to avoid bogging down during cuts, so make sure your chainsaw can handle the length you need. By considering these power requirements, you'll guarantee a smoother and more effective milling experience.

Bar Length Compatibility

Selecting the right bar length for your chainsaw is just as important as understanding its power requirements. Chainsaw mills are designed to accommodate specific bar lengths, which can range from 14 inches to over 48 inches. The bar length directly impacts the maximum width of the lumber you can cut. Shorter bars typically limit your cutting width, while longer bars provide the flexibility to tackle wider cuts, making them ideal for larger logs.

When you're choosing a chainsaw mill, it's vital to guarantee that the bar length matches the mill's compatibility requirements. If you want peak cutting performance, this alignment is essential. Using a chainsaw with a longer bar can be advantageous, especially if you plan to mill various lumber sizes. However, always stick to the bar length recommended by the mill's manufacturer. This adherence not only enhances operational efficiency but also safeguards your safety during milling.

Weight and Portability

Weight plays an essential role in determining how easily you can maneuver your chainsaw while milling lumber. Lighter models, ideally weighing less than 15 pounds, make it easier for you to handle and transport the tool, especially during extended use or when working in remote locations.

When you're milling, consider the balance of the chainsaw. A well-balanced tool reduces user fatigue and enhances control, allowing you to work more efficiently. Pay attention to features like a compact design and carry handles, which can greatly improve portability. These features simplify moving the chainsaw between different work sites or transporting it in your vehicle.

As you weigh your options, prioritize chainsaws designed to be lightweight without sacrificing durability. This combination guarantees that you can maneuver the tool with ease while also maintaining its longevity over time. Remember, the right weight not only aids in portability but also contributes to a more enjoyable milling experience. By choosing a chainsaw that fits these criteria, you'll be better equipped to tackle your lumber milling tasks effectively and comfortably.

Material Durability

When choosing a chainsaw for milling lumber, how do you guarantee it can withstand the rigors of the job? The key lies in the materials used in its construction. Opt for chainsaws made with high-quality steel and aluminum, as these components can handle the stress of cutting through dense hardwoods without succumbing to wear. Look for models crafted from aerospace-grade aluminum and zinc-plated steel, which offer excellent resistance to corrosion and impact, extending your chainsaw's lifespan.

Additionally, make sure the bar and chain are made from robust materials that can endure the high torque and forces generated during milling. This durability is essential for achieving clean cuts and minimizing the risk of damage. Regular maintenance is also important; keeping your chainsaw in top shape enhances its performance, especially when milling thicker logs or working in challenging environments.

Lastly, chainsaw mills built with high-quality materials provide better stability and precision, significant for smooth and accurate lumber cuts. By focusing on material durability, you'll set yourself up for success in your milling endeavors.

Ease of Assembly

Ease of assembly is a crucial factor in choosing the right chainsaw for milling lumber. You want a chainsaw mill that simplifies the setup process, allowing you to get started quickly. Many chainsaw mills have been designed with fewer accessory parts, which means you won't spend excessive time piecing everything together. Clear instructions are often included to guide you through the assembly.

Look for portable chainsaw mills that can clamp directly to the chainsaw bar. This feature eliminates the need for drilling, making setup straightforward and convenient. However, don't overlook the importance of proper alignment for your first cut. Using leveling tools can help guarantee ideal accuracy, making a significant difference in your milling results.

User feedback consistently highlights ease of installation as fundamental when choosing a chainsaw mill. While some models may require a bit of practice to achieve efficient cutting, others boast adjustable components that accommodate various cutting sizes and styles. By prioritizing ease of assembly, you'll save time and frustration, allowing you to focus on the task at hand—milling lumber effectively.

Cutting Depth Capacity

Cutting depth capacity plays an essential role in your lumber milling projects, as it directly influences the thickness of slabs you can produce. Typically, you can expect to mill slabs ranging from 1/2 to 13 inches, depending on the milling attachment you choose. To guarantee ideal cutting depth and efficiency, it's vital to select a chainsaw with a minimum engine displacement of 50cc.

Additionally, the compatibility between the chainsaw bar length and the milling attachment greatly affects the maximum cutting depth. Longer bars enable you to make deeper cuts and handle wider planks. If you're aiming for smoother and more efficient cuts, consider using a ripping chain instead of a standard one. This can enhance your cutting depth capacity and help you tackle thicker logs more effectively.

Lastly, adjusting the milling height and width settings on your chainsaw mill attachment lets you customize the cutting depth to meet the specific requirements of your projects. By taking these factors into account, you'll be better equipped to choose a chainsaw that suits your lumber milling needs and maximizes your efficiency.

Frequently Asked Questions

How Do I Maintain My Chainsaw for Optimal Milling Performance?

To maintain your chainsaw for peak milling performance, keep it clean and well-lubricated. Regularly check the chain tension and sharpen the chain as needed. Replace the air filter and spark plug periodically to guarantee efficient operation. Inspect the bar for wear and clean the grooves to avoid buildup. Finally, store it properly, keeping it dry and protected from the elements, to extend its lifespan and enhance performance during milling tasks.

What Safety Gear Should I Wear While Milling Lumber?

When you're milling lumber, wearing the right safety gear is vital. Start with a hard hat to protect your head from falling debris. Use safety goggles to shield your eyes from sawdust and flying particles. Hearing protection is essential too, as chainsaws can be loud. Don't forget cut-resistant gloves and durable boots to safeguard your hands and feet. Finally, consider wearing chainsaw chaps for added protection against accidental cuts. Stay safe while you work!

Can I Use Any Chainsaw for Milling Lumber?

Using any chainsaw for milling lumber is like trying to bake a cake with a frying pan; it just won't work well. You need a chainsaw that can handle the demands of milling, which means it should have a powerful engine and a suitable bar length. While some standard chainsaws might manage, they won't give you the efficiency or precision needed. Investing in a specialized milling chainsaw will make your lumber-cutting experience much smoother.

How Do I Properly Sharpen Chainsaw Blades for Milling?

To properly sharpen your chainsaw blades for milling, you'll want to use a round file that matches the chain's pitch. Start by securing the chainsaw in a vice, then file each tooth at the correct angle, guaranteeing you maintain the same number of strokes per tooth. Don't forget to adjust the depth gauge as needed. Regularly checking and sharpening your blades will guarantee a smoother cut and extend the life of your chainsaw.

What Type of Wood Is Best for Milling With a Chainsaw?

Did you know that hardwoods like oak and maple can grow up to 100 feet tall? When you're milling with a chainsaw, these dense, durable woods are ideal. They provide strength and longevity, making them perfect for furniture and flooring. Softwoods, like pine and cedar, can also work well, especially for outdoor projects. Ultimately, it depends on your project needs, but hardwoods typically yield the best results for quality lumber.

Wrapping Up

Ultimately, choosing the right chainsaw for milling lumber can feel like finding a needle in a haystack, but it doesn't have to be that hard! By considering options like the Zozen Portable Chainsaw Mill or the Granberg models, you'll be well on your way to tackling any lumber project with ease. Remember, the perfect chainsaw can turn your woodwork dreams into reality, so pick wisely and let your creativity soar!